Verzending 24–48 u • Levering in de hele EU • Veilige chemieverpakking

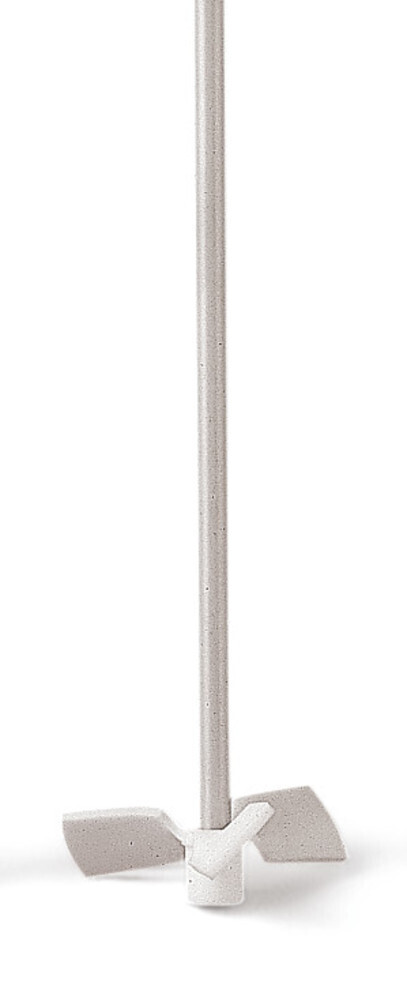

Stirring bars Propeller, 10 mm, 1 piece

SKU K079.1

€ 327,85

In stock

1

Save this product for later

Stirring bars Propeller, 10 mm, 1 piece

Product Details

HS code: 84799070

Material: Stainless steel

EAN: 8721028072627

Brand: Bohlender

Material: stainless steel, coated with PTFE.

The stirrer unit is made entirely of PTFE. A stainless steel core provides the required hold in the clamping ring of the stirrer. The stirrer unit is firmly anchored to the shaft: it is not loosened by continued turning of the medium after the stirrer has been turned off. Since the materials to be turned only have contact with PTFE, the stirrer shafts are virtually resistant to chemicals and allow high application temperatures. The dimensions of the stirrer shafts match the (KPG) glass stirrer shafts and are therefore interchangeable at any time. With tapered collet, for easier clamping of stirrer shafts.

Stirring blades Propeller

Technical Information

| Dimensions | Sheet Ø 75 mm |

| Ø Shaft | 10 mm |

| Ø Clamping | 8 mm |

| Total length | 450 mm |

Agitator types

Anchor agitator: Reduced deposits on the vessel wall. Tangential stream with high shear rate. Suitable for semi-fluid mediums (medium to high viscosity).Dissolver agitator: Radial stream. High turbulence and shear forces.For use at medium to high speeds.Surface agitator: Less turbulence. Gentle handling of the product.For use at low to medium speeds.Half-moon agitator: The semi-round shape of the agitator blade is ideally suited to agitating in round-bottomed flasks, the tip function makes it easy to insert the agitator shaft into vessels which have been ground or have a narrow neck. Suitable for agitating liquids with low to medium viscosity. For use at medium speeds.Propeller agitator: Standard agitator. Axial direction. For mixing mediums with low to medium viscosity. Ideal for homogenising and suspending.Centrifugal agitator: Double-leaf; thanks to the moveable agitator leaf, the agitator shaft can be easily inserted into the vessels with a narrow neck. The leaves open when the speed increases. For use at medium to high speeds.

You May Also Like

End user declaration required

Barium chloride dihydrate 99+% extra pure 2.5 Kilogram

Barium chloride dihydrate 99+% extra pure 2.5 Kilogram

Only for registered companies

SKU BAC9345.4

€ 73,13

Display prices in:EUR