Molybdenum rod 99.95% 1 mm diameter 1 m

SKU 903645

€ 68,31

In stock

1

Save this product for later

Molybdenum rod 99.95% 1 mm diameter 1 m

Product Details

CAS number: 7439-98-7

Cation: Mo

Packaging: 1 m

EAN: 8721028237224

Brand: Laboratoriumdiscounter

1 mm diameter

Molybdenum rod is a high-performance metal alloy known for its exceptional strength, heat resistance, and corrosion resistance. With its unique properties, molybdenum rod is widely used in various industries, including aerospace, automotive, and electronics. Whether it's for structural components or electrical applications, molybdenum rod offers unmatched durability and reliability.

When working with Molybdenum rods, it is important to follow these safety instructions: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, gloves, and a lab coat or protective clothing. Molybdenum rods can generate sparks and may cause eye or skin irritation. 2. Ventilation: Ensure that you are working in a well-ventilated area or use local exhaust ventilation to prevent the accumulation of fumes or dust. Molybdenum rods can release harmful fumes when heated or cut. 3. Handling: Use caution when handling Molybdenum rods, as they can be heavy and may cause injury if dropped. Lift and carry them with proper support and avoid dragging or sliding them across surfaces. 4. Fire Safety: Molybdenum rods are flammable when exposed to high temperatures. Keep them away from open flames or other ignition sources. Have a fire extinguisher nearby and know how to use it. 5. Cutting and Machining: If cutting or machining Molybdenum rods, use appropriate tools and techniques. Avoid excessive heat generation, as it can release toxic fumes. Use lubricants or coolants to minimize heat buildup and wear a respirator if necessary. 6. Storage: Store Molybdenum rods in a dry and well-ventilated area, away from moisture, heat sources, and incompatible materials. Keep them in a secure location to prevent accidental damage or injury. 7. Disposal: Dispose of Molybdenum rods according to local regulations and guidelines. Do not dispose of them in regular trash or pour any leftover materials down the drain. 8. Training: Ensure that all personnel working with Molybdenum rods are properly trained on their safe handling, storage, and disposal procedures. Regularly review and update safety protocols to maintain a safe working environment. Remember, these safety instructions are general guidelines, and it is essential to consult specific safety data sheets and follow any additional safety recommendations provided by the manufacturer or your organization.

Please note, not all safety data for this product is available on our website, for a complete list of P en H sentences and other safety instructions please request the MSDS at our customer service

Molybdenum rod is a high-performance metal alloy known for its exceptional strength, heat resistance, and corrosion resistance. With its unique properties, molybdenum rod is widely used in various industries, including aerospace, automotive, and electronics. Whether it's for structural components or electrical applications, molybdenum rod offers unmatched durability and reliability.

When working with Molybdenum rods, it is important to follow these safety instructions: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, gloves, and a lab coat or protective clothing. Molybdenum rods can generate sparks and may cause eye or skin irritation. 2. Ventilation: Ensure that you are working in a well-ventilated area or use local exhaust ventilation to prevent the accumulation of fumes or dust. Molybdenum rods can release harmful fumes when heated or cut. 3. Handling: Use caution when handling Molybdenum rods, as they can be heavy and may cause injury if dropped. Lift and carry them with proper support and avoid dragging or sliding them across surfaces. 4. Fire Safety: Molybdenum rods are flammable when exposed to high temperatures. Keep them away from open flames or other ignition sources. Have a fire extinguisher nearby and know how to use it. 5. Cutting and Machining: If cutting or machining Molybdenum rods, use appropriate tools and techniques. Avoid excessive heat generation, as it can release toxic fumes. Use lubricants or coolants to minimize heat buildup and wear a respirator if necessary. 6. Storage: Store Molybdenum rods in a dry and well-ventilated area, away from moisture, heat sources, and incompatible materials. Keep them in a secure location to prevent accidental damage or injury. 7. Disposal: Dispose of Molybdenum rods according to local regulations and guidelines. Do not dispose of them in regular trash or pour any leftover materials down the drain. 8. Training: Ensure that all personnel working with Molybdenum rods are properly trained on their safe handling, storage, and disposal procedures. Regularly review and update safety protocols to maintain a safe working environment. Remember, these safety instructions are general guidelines, and it is essential to consult specific safety data sheets and follow any additional safety recommendations provided by the manufacturer or your organization.

Please note, not all safety data for this product is available on our website, for a complete list of P en H sentences and other safety instructions please request the MSDS at our customer service

You May Also Like

Ethyl 5-(3-nitrophenyl)-5-oxovalerate, 97.0%, 2g

Ethyl 5-(3-nitrophenyl)-5-oxovalerate, 97.0%, 2g

SKU F207939-2G

€ 1 989,90

End user declaration required

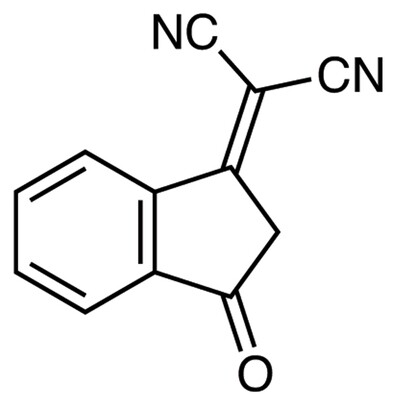

3-(Dicyanomethylidene)indan-1-one>98.0%(GC)1g

3-(Dicyanomethylidene)indan-1-one>98.0%(GC)1g

Only for registered companies

SKU D2054-1G

€ 132,00

Display prices in:EUR

![N-(2,3-Dimethyl-5,6,7,8-tetrahydrofuro[2,3-b]quinolin-4-yl)-2-(2-oxopyrrolidin-1-yl)acetamide, 95.0%, 1g N-(2,3-Dimethyl-5,6,7,8-tetrahydrofuro[2,3-b]quinolin-4-yl)-2-(2-oxopyrrolidin-1-yl)acetamide, 95.0%, 1g](https://d2j6dbq0eux0bg.cloudfront.net/images/88473019/4780628027.png)

![Poly[2-(Dimethylamino)ethyl Methacrylate] Number Average Molecular Wt. 50000500mg Poly[2-(Dimethylamino)ethyl Methacrylate] Number Average Molecular Wt. 50000500mg](https://d2j6dbq0eux0bg.cloudfront.net/images/88473019/4044913474.jpg)

![ETHYL 4-(4-CHLORO-1H-PYRAZOLO[3,4-D]PYRIMIDIN-1-YL)BENZOATE, 95.0%, 5g ETHYL 4-(4-CHLORO-1H-PYRAZOLO[3,4-D]PYRIMIDIN-1-YL)BENZOATE, 95.0%, 5g](https://d2j6dbq0eux0bg.cloudfront.net/images/88473019/4769830102.png)